Some good stuff got done this week even though I didn’t melt much solder.

I had an amateur radio testing session on Saturday. It was a busy day with lots of new hams passing there Technician, some going on to pass the General exam, and even an Extra! We also had several upgrades to General and Extra.

For me the session was also a good learning experience as a VE because I had the opportunity to get some training in another job with the group.

We basically have three jobs split among the VEs present at any given session; two administrative jobs, and a panel of test examiners. I have been participating as an examiner for the last several months. Today I received some training for the administrative side of things.

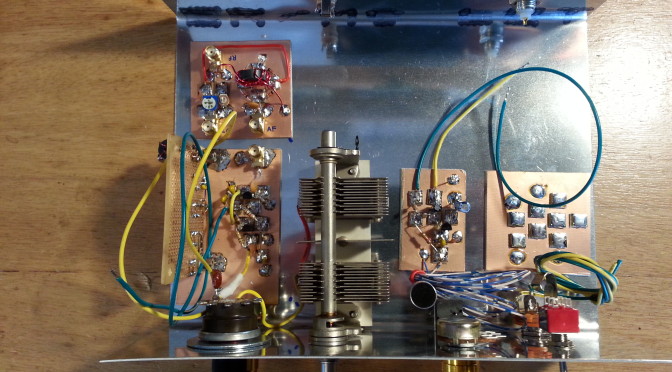

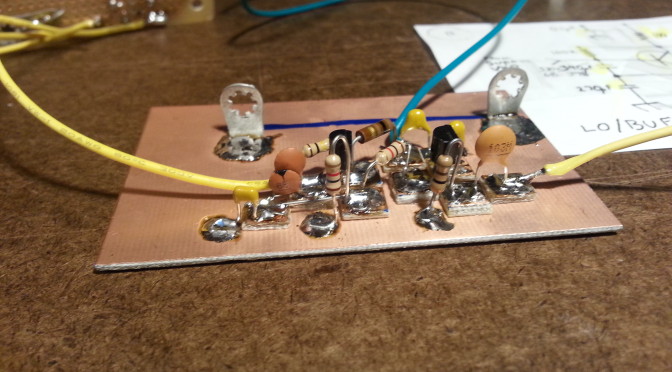

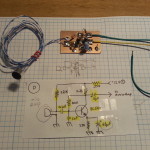

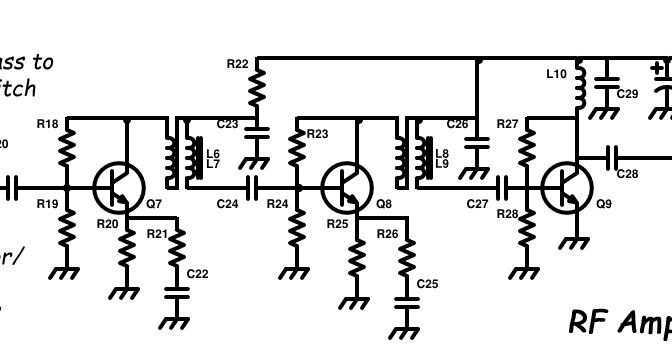

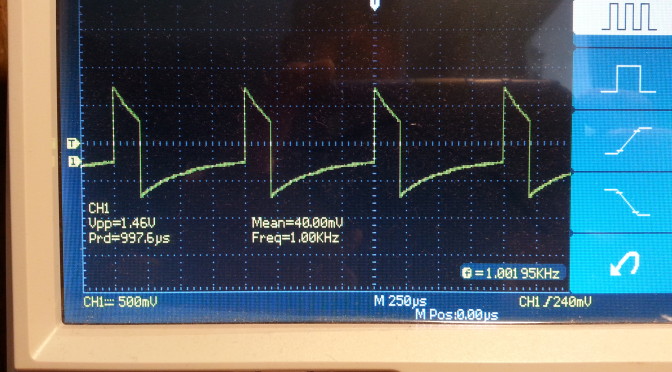

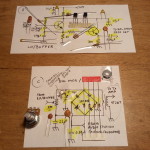

I have been putting off the testing on the Beach 40 until I get the last few details finished on the audio and RF amps as well as the LP filter. This week I am playing beginning of the month catch-up with the day job so time is short.

Also tied to everything else is the change over from Windows to Linux. I have deleted the Win partition on the laptop and am now running full on Linux. I am loosing two programs I liked but just couldn’t get them to work with Linux native or emulated and I don’t want to run virtual machines. I still have all of the data, and I do have a Windows 7 laptop in the shop I basically only use for the web browser.

The programs I am loosing are Quicken and Business Plan Pro. BPP will just go away. I exported all of the business plans I have put together over the last decade to .doc files which I can access through OpenOffice. I can use the previous plans to build new ones as needed in document formats.

Quicken is the one giving me headaches. Supposedly you can export the data to a file for import to Skrooge. No joy. After several exports and several hours I made the contagious/stupid decision to just go back and reenter all the data for this year. It sounds a lot worse than it is. I will just do one month at a time and by the end of this month I should be all caught up. Not to mention very familiar with the new software.

I have found replacements or versions that will run on Linux or in emulation for all of my radio software an in fact found some new stuff that looks mighty interesting. Big plus here.

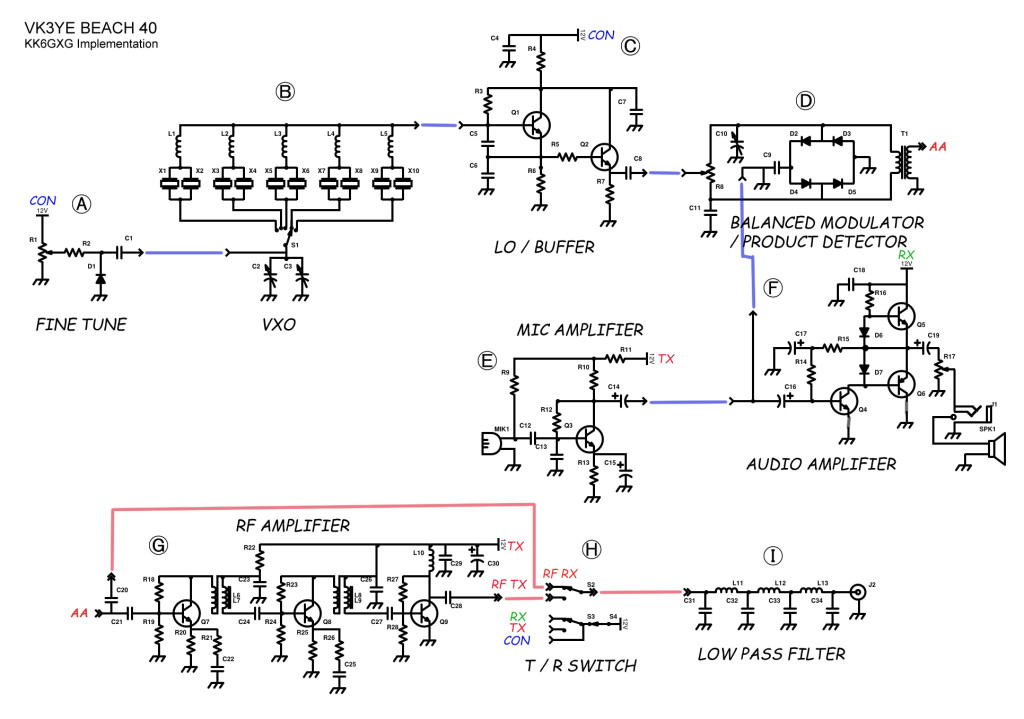

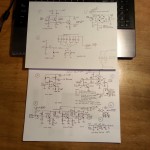

Along with the radio specific software, I found gEDA Schematic Editor. WOOT! It took a little getting used to the interface and component placement, but I like the results a lot. I have been redrawing the schematics I originally did on schematics.com for the Beach 40 and think they look much better. I will be posting them soon to the build page. A good thing too because there are some errors on those schematics. Ooops!

One last update before I go, I was working on test prep for my commercial radio license a while ago but got sidetracked by all of the build projects and the day job. One of my goals for second/third quarter is to take my commercial radio exams, at least two of the three anyway, and get my commercial license. So I will be committing some of my limited time to that endevor over the next few weeks. The build will continue, I still hope to have the Beach 40 up by Field Day, but I need to budget more time to the Day Job/Future Day Job.

Anyway, I have 0.5TB of files syncing with Google Drive and a pile of accounting stuff that needs to find a new home in Skrooge so that’s it for today.

Until next time, 73,

~Jon KK6GXG

e only hiccough was technician error. I got all of the components soldered in, mounted the board in the back of the case, mounted the LCD, and plugged in the battery. When I turned on the power switch I got nothing. I knew from reading the instructions

e only hiccough was technician error. I got all of the components soldered in, mounted the board in the back of the case, mounted the LCD, and plugged in the battery. When I turned on the power switch I got nothing. I knew from reading the instructions

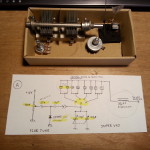

With this project I wanted to keep things as simple as possible and use off-the-shelf materials that are easily found and relatively cheap. One of the pieces I wanted was a simple piece of hardware I have seen many times. I have even bought it and used it, a three or four-inch long nut. We used to use them for connecting CB antennas to rigid mounts with a nylon spacer block on the bottom and a bolt. The same basic format used to connect the spring mount base for mobile use. The intended use in this project is to connect the steel spike at the top of the antenna to the fiberglass body.

With this project I wanted to keep things as simple as possible and use off-the-shelf materials that are easily found and relatively cheap. One of the pieces I wanted was a simple piece of hardware I have seen many times. I have even bought it and used it, a three or four-inch long nut. We used to use them for connecting CB antennas to rigid mounts with a nylon spacer block on the bottom and a bolt. The same basic format used to connect the spring mount base for mobile use. The intended use in this project is to connect the steel spike at the top of the antenna to the fiberglass body. Anyway, the next closest thing was turnbuckle bodies. The “solid” bodies were aluminum and the open body type looked like nickel plate and galvanized. I ended up buying an open body style, but it really brought about several issues. First and foremost are the mechanical issues. The contact points on both ends are fairly small, less than half an inch. Even with the fiberglass rod and the steel spike screwed down all the way and touching there is still only a half inch of contact on either end. These things are intended for stresses in tension not in bending which s what they will be exposed to in this application.

Anyway, the next closest thing was turnbuckle bodies. The “solid” bodies were aluminum and the open body type looked like nickel plate and galvanized. I ended up buying an open body style, but it really brought about several issues. First and foremost are the mechanical issues. The contact points on both ends are fairly small, less than half an inch. Even with the fiberglass rod and the steel spike screwed down all the way and touching there is still only a half inch of contact on either end. These things are intended for stresses in tension not in bending which s what they will be exposed to in this application.