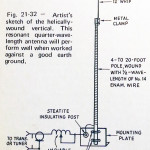

Today was a good antenna day. I finally got the PVC cover on the 40 meter helically-wound antenna I started back in April. I have been using the antenna without the cover as a test antenna next to the bench but it’s time to get it up on the roofline for some actual use.

Today was a good antenna day. I finally got the PVC cover on the 40 meter helically-wound antenna I started back in April. I have been using the antenna without the cover as a test antenna next to the bench but it’s time to get it up on the roofline for some actual use.

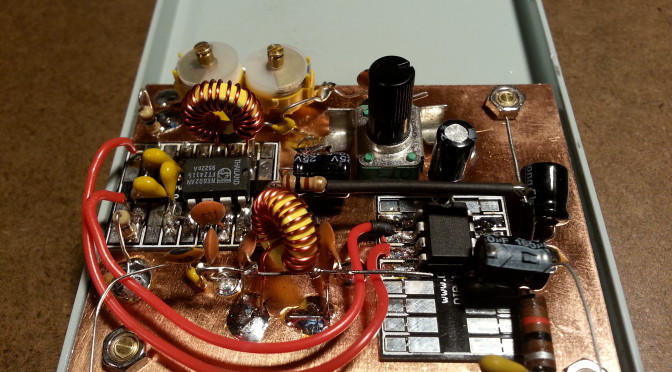

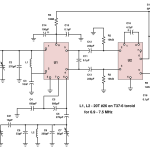

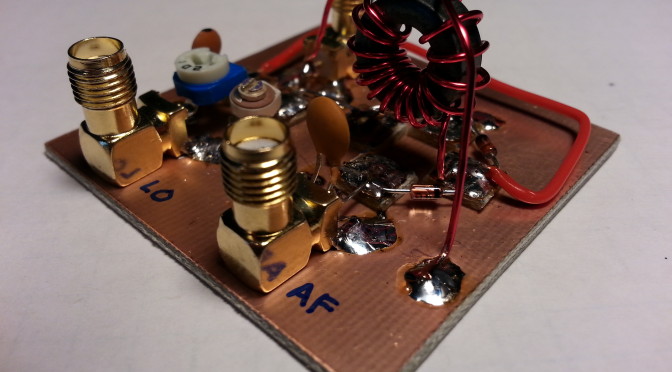

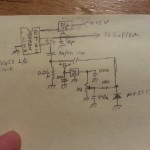

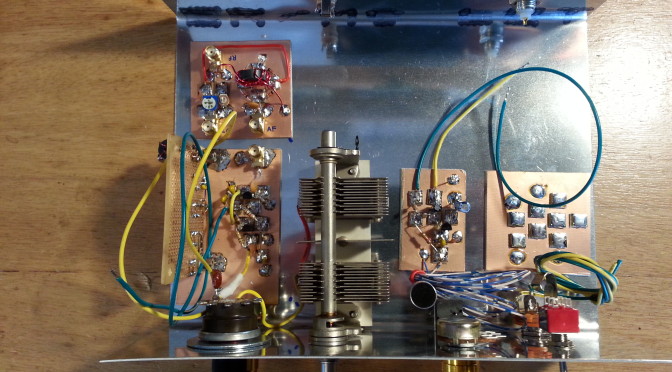

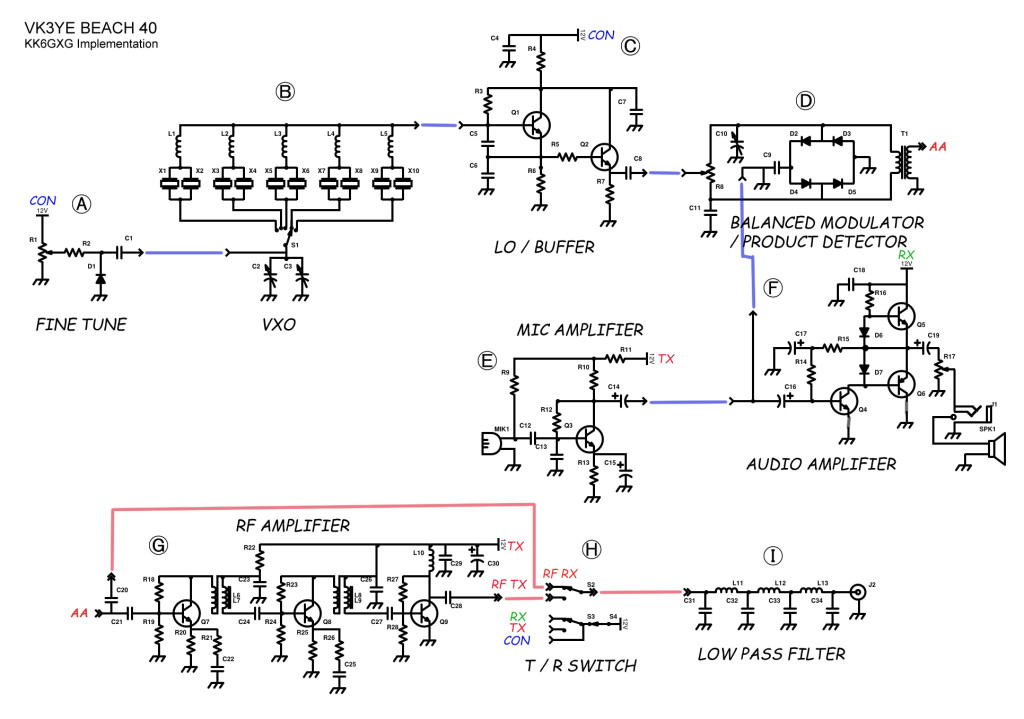

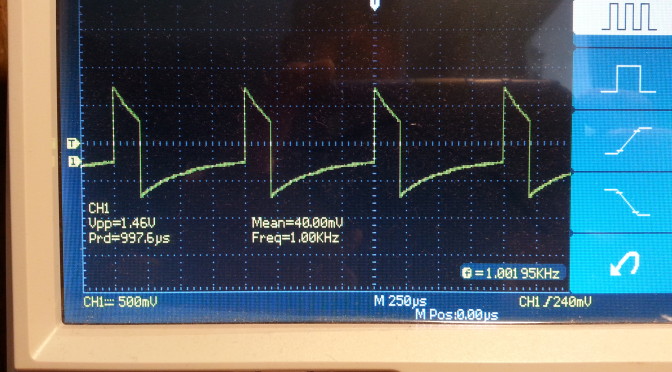

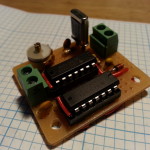

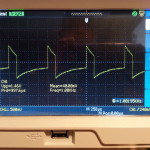

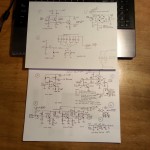

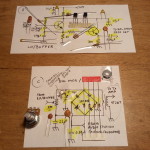

By “actual use” I am referring to the Beach 40 project that is back in motion now that I have a VXO that pulls more than 1.8 kHz of selectivity. Yay 148 kHz selectivity! Now all I need to do is get the Tx/Rx switching working for the transceiver to be operational.

Another antenna project completed today is the 2 meter twin-lead J-Pole. This one was also waiting for a PVC cover so it could be mounted on a pole. The original design was intended as a portable antenna but the twin-lead J-Pole on any frequency above 50 MHz lends itself well to mounted vertical use, it just needs a housing to keep it in the vertical position.

Another antenna project completed today is the 2 meter twin-lead J-Pole. This one was also waiting for a PVC cover so it could be mounted on a pole. The original design was intended as a portable antenna but the twin-lead J-Pole on any frequency above 50 MHz lends itself well to mounted vertical use, it just needs a housing to keep it in the vertical position.

This little antenna works really well. On numerous occasions I have been unable to ping the local repeaters with my HT with the stock or aftermarket antennas for handhelds. If I attach the twin-lead J-Pole I can actually get out and participate in the nets. With this antenna up in the air at roofline I should have no problems working any of the local repeaters including the packet and Winlink towers.

Speaking of which, I want to get into digital modes once I get the antennas up in the air. I’m not quite up to building a TNC from scratch so I need to save up a hundred and fifty bucks to get digital rolling. Soon…

The other antenna project today was a new-start. When the 2 and 40 meter antennas go up I also plan on attaching a 70 cm half-wave vertical with counterpoise. This one is an experiment. I originally planned on building a 70 cm full-wave twin-lead J-Pole, and I likely still will, but I wanted to see if I could make a vertical with counterpoise that works well. I may even mod this one into a full-wave vertical with half-wave counterpoise radials. Dunno. Like I said, this is an experiment.

The other antenna project today was a new-start. When the 2 and 40 meter antennas go up I also plan on attaching a 70 cm half-wave vertical with counterpoise. This one is an experiment. I originally planned on building a 70 cm full-wave twin-lead J-Pole, and I likely still will, but I wanted to see if I could make a vertical with counterpoise that works well. I may even mod this one into a full-wave vertical with half-wave counterpoise radials. Dunno. Like I said, this is an experiment.

Another near-term antenna project, as-of-yet not started, is an aviation band twin-lead J-Pole set up like the 2 meter one. Being a pilot and mechanic, at some point I would like to have either a hangar at a local airport or a small strip at home to work on restorations, so it would make sense to have an AvBand radio in the shop. I have a Vertex Standard (Yaesu) HT for aviation VHF, it just needs an external antenna. I also have a few old radios salvaged from aircraft that would never make it back into an aircraft, but may be suitable for base station operations.

I have a number of other antenna experiment/projects in various configurations, in particular 2 m and 70 cm yagi and/or helical beam antennas suitable for satellite and moon bounce communication. But these are for the future. I also want to build some highly directional antennas for radio orienteering and high-gain narrow-beam antennas for really low power communications.

As for the “More” in the title, once I finish the 40 m transceiver I plan on building a 20 and 10 meter versions. I also have an idea for simple low power beacon transmitters I want to play with. I also want to get set up for QRSS, WSPR, and APRS.

Lots to do. One step at a time.

Till next time, 73,

~Jon KK6GXG

To keep domestic peace I have not been building on the

To keep domestic peace I have not been building on the

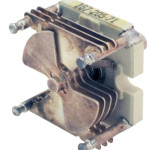

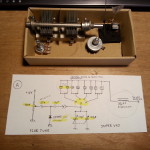

With this project I wanted to keep things as simple as possible and use off-the-shelf materials that are easily found and relatively cheap. One of the pieces I wanted was a simple piece of hardware I have seen many times. I have even bought it and used it, a three or four-inch long nut. We used to use them for connecting CB antennas to rigid mounts with a nylon spacer block on the bottom and a bolt. The same basic format used to connect the spring mount base for mobile use. The intended use in this project is to connect the steel spike at the top of the antenna to the fiberglass body.

With this project I wanted to keep things as simple as possible and use off-the-shelf materials that are easily found and relatively cheap. One of the pieces I wanted was a simple piece of hardware I have seen many times. I have even bought it and used it, a three or four-inch long nut. We used to use them for connecting CB antennas to rigid mounts with a nylon spacer block on the bottom and a bolt. The same basic format used to connect the spring mount base for mobile use. The intended use in this project is to connect the steel spike at the top of the antenna to the fiberglass body. Anyway, the next closest thing was turnbuckle bodies. The “solid” bodies were aluminum and the open body type looked like nickel plate and galvanized. I ended up buying an open body style, but it really brought about several issues. First and foremost are the mechanical issues. The contact points on both ends are fairly small, less than half an inch. Even with the fiberglass rod and the steel spike screwed down all the way and touching there is still only a half inch of contact on either end. These things are intended for stresses in tension not in bending which s what they will be exposed to in this application.

Anyway, the next closest thing was turnbuckle bodies. The “solid” bodies were aluminum and the open body type looked like nickel plate and galvanized. I ended up buying an open body style, but it really brought about several issues. First and foremost are the mechanical issues. The contact points on both ends are fairly small, less than half an inch. Even with the fiberglass rod and the steel spike screwed down all the way and touching there is still only a half inch of contact on either end. These things are intended for stresses in tension not in bending which s what they will be exposed to in this application.