I picked up some hardware to connect the antenna bits together into one cohesive unit. Sometimes with hardware you have to just go to the store and look around for solutions to a specific problem or situation.

With this project I wanted to keep things as simple as possible and use off-the-shelf materials that are easily found and relatively cheap. One of the pieces I wanted was a simple piece of hardware I have seen many times. I have even bought it and used it, a three or four-inch long nut. We used to use them for connecting CB antennas to rigid mounts with a nylon spacer block on the bottom and a bolt. The same basic format used to connect the spring mount base for mobile use. The intended use in this project is to connect the steel spike at the top of the antenna to the fiberglass body.

With this project I wanted to keep things as simple as possible and use off-the-shelf materials that are easily found and relatively cheap. One of the pieces I wanted was a simple piece of hardware I have seen many times. I have even bought it and used it, a three or four-inch long nut. We used to use them for connecting CB antennas to rigid mounts with a nylon spacer block on the bottom and a bolt. The same basic format used to connect the spring mount base for mobile use. The intended use in this project is to connect the steel spike at the top of the antenna to the fiberglass body.

I remember buying these at Orchards Supply and Ace Hardware. I never had a problem finding one back in the 80s. Yesterday I went to OSH and Home Depot and the employees looked at me like I was from mars. They had these little 1-1.5 inch versions for connecting all-thread, which is what I am looking for, just longer. No clue. Nothing registered on their faces, even with the smaller version in my hand.

Anyway, the next closest thing was turnbuckle bodies. The “solid” bodies were aluminum and the open body type looked like nickel plate and galvanized. I ended up buying an open body style, but it really brought about several issues. First and foremost are the mechanical issues. The contact points on both ends are fairly small, less than half an inch. Even with the fiberglass rod and the steel spike screwed down all the way and touching there is still only a half inch of contact on either end. These things are intended for stresses in tension not in bending which s what they will be exposed to in this application.

Anyway, the next closest thing was turnbuckle bodies. The “solid” bodies were aluminum and the open body type looked like nickel plate and galvanized. I ended up buying an open body style, but it really brought about several issues. First and foremost are the mechanical issues. The contact points on both ends are fairly small, less than half an inch. Even with the fiberglass rod and the steel spike screwed down all the way and touching there is still only a half inch of contact on either end. These things are intended for stresses in tension not in bending which s what they will be exposed to in this application.

The next issue is the left-hand thread of one end of the turnbuckle. I was willing to deal with this I even started looking for a LH die to thread the fiberglass and this is where I decided to take a step back, reevaluate, and take stock of my options.

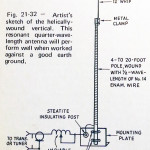

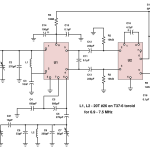

At this point the base end has been worked out. The right-angle conduit box is the base and will have 12 inches of half-inch PVC conduit inserted in the port that is parallel to the box. The wound fiberglass rod will be inserted through the PVC pipe into the base. I will cut off all but an eight-inch of the other port which will be the outside housing of the SO-239 which will be inserted from the inside of the box.

At this point the base end has been worked out. The right-angle conduit box is the base and will have 12 inches of half-inch PVC conduit inserted in the port that is parallel to the box. The wound fiberglass rod will be inserted through the PVC pipe into the base. I will cut off all but an eight-inch of the other port which will be the outside housing of the SO-239 which will be inserted from the inside of the box.

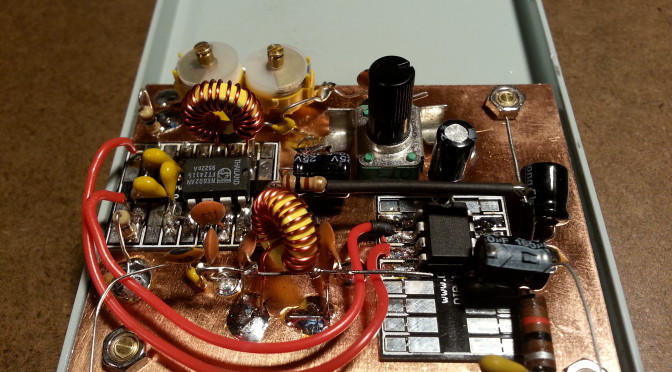

Once the antenna coil is soldered to the SO-239 on the inside of the box I will fill the box and the PVC pipe with polyester resin making the base a single solid weatherproof piece. The reason for the PVC pipe being 12 inches long is to provide a solid place for mounting standoffs to be attached. All done with off the shelf hardware and materials with only one minor modification and no special tools.

Now back to the top end and mounting the steel spike to the fiberglass rod. The most direct method is using the all-thread nut I originally wanted to use. Since it is not available, and a sufficient replacement in size, complexity, and structural strength does not appear to be an off the shelf item, at least around here, I guess I need to make one.

I thought of welding nuts together and other welded configurations but they all require more work than what is really the simplest solution. Drill a piece of half-inch bar stock and tap it for 5/16″ 18 threads per inch. I already picked up the die, now I just need the tap and drill.

This solution does require a couple of tools, tap and die along with their respective handles, the right size drill (an F), and a little machining. This operation isn’t really a big deal. If you have a bench top drill press it will make things easier, but it can be done by hand with a bench vice.

The remaining decision is material for the threaded block. I know I have aluminum and I think I have both steel and brass that are the right size, or at least useable. I am leaning towards the steel or brass. Aluminum and steel don’t play well together when there is the potential for moisture penetration between the surfaces making galvanic corrosion an issue as well as heat dissipation and mechanical contact issues.

More to come on this subject soon.

73,

~Jon KK6GXG