The topic of current events arose in conversation this morning. The two major events that came up were the Nepal earthquake with the ongoing humanitarian aid efforts there and the situation in Baltimore.

The topic of current events arose in conversation this morning. The two major events that came up were the Nepal earthquake with the ongoing humanitarian aid efforts there and the situation in Baltimore.

In Nepal not only is there the topic of the humanitarian aid, but also the political elements involved with the relief communications problems. There is a long story about amateure radio and the Nepal governments apparent conflicts with the emergency preparations that some hams have been working on for years. It may have a connection to many lost lives which may have been saved had they not been blocked by government efforts. I am getting this information from a directly involved party, and I have every reason to believe him, but I know very little about the actual situation from first-hand knowledge. So while my heart goes out to the people of Nepal, it is hard to make educated comments on the political front.

With Baltimore, well, this is a tough subject to broach. As the title of this post says, my head has been in the sand. I know very little of what is actually going on. I did see the video of the mother who when she saw her son rioting and throwing rocks at police went down to the site, found him, and smacked him around. Nice to see a parent taking responsibility for their child by the way. I don’t know how much of or even if that story is true, I only saw one blog post and a video clip.

Where I’m going with this is I haven’t been paying a lot of attention to the media’s reports of what’s going on in the world lately. Mainly because these days the media, all media, has an agenda. They all want to have eyes on their “data.” Their revenue stream depends on viewership, so they must sell there “data” in whatever form to make money. Big Media has a market and a demographic they are selling to, so their perspective is skewed to that demographic. Further complicating things is the political connection of the management and owners of the media outlet further skewing the perspective and agenda.

Just to be perfectly clear, I don’t like or trust Big Media. I bet you already figured that out though. As the quote goes, “Follow the money.” Who has most of the money in the US, media and financial institutions. Who holds the most sway with elected officials, media and financial. Who shapes public opinion, media and financial. Do you think credit companies and banks want you to be debt free? Hell no! They would go broke. Do you think Big Media would be making billions if there was no public conflict? Same thing, hell no!

There are miscreants, there are bad cops, and the behavior of both is reprehensible, but these bad actors are in very small numbers. They are the instigators, knowingly or not, doing a job they are employed to do. Who do you think is at the root of backing and organizing the instigators?… This isn’t just about Baltimore. It is the direction the country is being manipulated. I know almost nothing about the situation in Baltimore. I have heard a lot, but I don’t KNOW very much at all. I refuse to be manipulated into an opinion by someone elses political/financial agenda.

I can only loosely observe trends. There are few verifiable facts being made available, and fewer sources that can be trusted to provide these facts with any modicum of objectivity. Observing trends and trying to sus out which way the wind is blowing is about the best we can hope for. Getting incensed about something because the media says its true only serves to distract us.

When a population is polarized, agitated, and distracted it doesn’t see the real problems it faces, the real instigators. Who is polarizing, agitating, and distracting us? Follow the money.

~FlyBoyJon

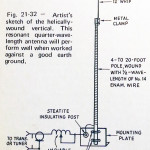

With this project I wanted to keep things as simple as possible and use off-the-shelf materials that are easily found and relatively cheap. One of the pieces I wanted was a simple piece of hardware I have seen many times. I have even bought it and used it, a three or four-inch long nut. We used to use them for connecting CB antennas to rigid mounts with a nylon spacer block on the bottom and a bolt. The same basic format used to connect the spring mount base for mobile use. The intended use in this project is to connect the steel spike at the top of the antenna to the fiberglass body.

With this project I wanted to keep things as simple as possible and use off-the-shelf materials that are easily found and relatively cheap. One of the pieces I wanted was a simple piece of hardware I have seen many times. I have even bought it and used it, a three or four-inch long nut. We used to use them for connecting CB antennas to rigid mounts with a nylon spacer block on the bottom and a bolt. The same basic format used to connect the spring mount base for mobile use. The intended use in this project is to connect the steel spike at the top of the antenna to the fiberglass body. Anyway, the next closest thing was turnbuckle bodies. The “solid” bodies were aluminum and the open body type looked like nickel plate and galvanized. I ended up buying an open body style, but it really brought about several issues. First and foremost are the mechanical issues. The contact points on both ends are fairly small, less than half an inch. Even with the fiberglass rod and the steel spike screwed down all the way and touching there is still only a half inch of contact on either end. These things are intended for stresses in tension not in bending which s what they will be exposed to in this application.

Anyway, the next closest thing was turnbuckle bodies. The “solid” bodies were aluminum and the open body type looked like nickel plate and galvanized. I ended up buying an open body style, but it really brought about several issues. First and foremost are the mechanical issues. The contact points on both ends are fairly small, less than half an inch. Even with the fiberglass rod and the steel spike screwed down all the way and touching there is still only a half inch of contact on either end. These things are intended for stresses in tension not in bending which s what they will be exposed to in this application.

Today marks a first for me. Today was the first time I participated in an amateur radio license exam session as a Volunteer Examiner.

Today marks a first for me. Today was the first time I participated in an amateur radio license exam session as a Volunteer Examiner.